Crews use a crane to lift one of our cable car sheaves to restore it.

This Transit Month, we are going behind the scenes of our work to improve your Muni trips across the city.

Today, we shine the spotlight on San Francisco’s cable cars. These cars are more than just iconic symbols of the city. They are a source of pride for those who live here. (Sorry, Golden Gate Bridge – we love you, but these beautiful cars have been around much longer!).

Cable cars have been gliding down San Francisco streets since 1873. And the time has come to give them a little refresh. That’s why our teams are hard at work restoring the sheaves that help keep the cable cars running. This way, they can keep bringing joy for generations more.

Sheaves are critical to the cable car system. And, there are three interesting challenges we have solved to restore them.

Keeping our cable cars moving: Meet the sheaves

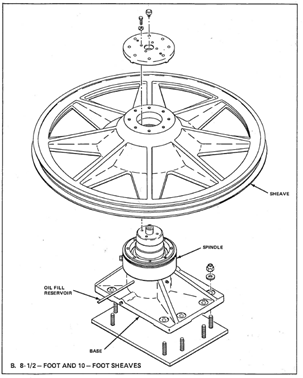

Cable car sheaves are large, grooved wheels that are eight to ten feet in diameter. They help guide the cables that move our cable cars along their routes. The sheaves can weigh anywhere between 6,800 to 8,300 pounds and are usually located under street intersections.

Because the sheaves are incredibly heavy and mostly underground, restoring them requires a lot of advance planning. It also requires expertise in refurbishing specialized parts.

That’s because San Francisco is the only city in the world that has a cable car system in operation. As a result, no company is producing new cable car parts. We can’t just go to a hardware store and pick a sheave off the shelf!

Right now, we are just over halfway finished with the work systemwide. We expect to complete the project by mid-fall. The last time the sheaves were completely replaced was in the 1980s.

As we work to finish this round of upgrades, we wanted to show you how our teams have solved a few exciting challenges.

Crews lift a refurbished sheave to prepare for placement in underground vault.

Top three challenges to refurbishing and replacing the cable car sheaves

1. Providing continuous service during critical upgrades.

Riding the cable cars is a special experience. We made sure there would always be at least one cable car segment in operation, even during workdays. Providing continuous service while the sheaves are replaced required a lot of coordination behind the scenes. To minimize impacts for everyone who wants to ride a cable car, we consulted community stakeholders near cable car routes or who serve the tourism industry.

Based on these conversations, we adjusted the work schedule so it doesn’t disrupt our local businesses and residents along the cable car routes too much. This meant limiting workdays to only one or two days a week.

2. Moving the massive sheaves to carry out restoration work.

The majority of the sheaves are under the streets at places where the cable cars make turns. Because of that, accessing the sheaves is not easy. Cranes and hydraulic lifts need to be maneuvered into place.

First, they help us lift the massive vault doors open so crews can access the sheaves. Then, they help lift the massive sheaves out and transport them over to the Cable Car Barn where refurbishing will happen.

3. Refurbishing and creating specialized parts.

When we restore sheaves, they get a full refurbishment from top to bottom. Our SFMTA crews are making sure that the sheaves are being thoroughly cleaned and repaired.

The photo below shows a sheave that is being lifted out of its vault so that it can receive some special care. This infrastructure doesn’t exist anywhere else in the world, so our crews are truly specialists in their field!

Lifting a cable car sheave out of its vault for upgrades.

In addition to each sheave getting a makeover, the assembly, or “foot,” that supports the sheave also gets refurbished. This assembly is what allows the sheave to spin as it guides the cable. Every single part of the sheave’s foot is separated and either refurbished or replaced as needed.

For any part of the foot that needs to be replaced, our crews must make it from scratch. This adds to the complexity and length of time to reassemble the entire foot and reinstall it. The illustration below shows all the pieces that make up a single sheave foot.

Illustration of the components that make up a cable car sheave foot.

And all of this work is worth it! San Francisco loves its cable cars, and we love that visitors to the city love our cable cars.

You can learn more about our beloved cable cars in a couple of episodes of our Taken with Transportation podcast. “Happy Birthday to a San Francisco Treasure” celebrates the cable car system’s 150th anniversary and chronicles its early history. And “Breaking Glass Ceilings Halfway to the Stars” profiles our first two female cable car grips. You can find them on our podcast webpage (SFMTA.com/Podcast) or wherever you listen.

If you would like to stay up-to-date about the cable car sheaves upgrades, please take a moment to sign up. You can choose email or text messages. You can also visit our project page for additional information.